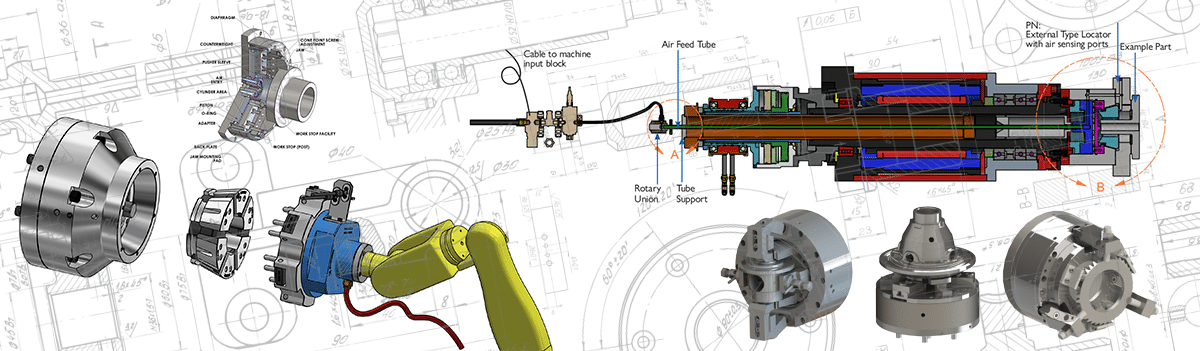

We understand not every workholding challenge can be solved with off the shelf product. Forkardt Hardinge designs, manufactures and tests custom workholding solutions every day that tackle some of the most complicated manufacturing challenges in the world. Let our team of experienced sales & design engineers help you with your custom workholding needs! Whether you’re dealing with out-of-round parts, challenging geometries, or unconventional materials, we have the expertise to provide innovative designs that meet your unique requirements. Our team excels in addressing complex engineering challenges, ensuring that you receive a precisely engineered solution that enhances your operational efficiency and effectiveness. Trust Forkardt Hardinge for bespoke solutions that perfectly fit your needs.

Minimizing downtime due to changeover is crucial for any manufacturer. Forkardt Hardinge addresses this need with a wide range of off-the-shelf to fully custom quick-change solutions that can significantly boost productivity. Our quick-change solutions can be coupled with automation or manual changing methods. Leveraging advanced engineering, precise machining, and robotic integration, Forkardt Hardinge’s quick-change solutions provide unparalleled versatility, accuracy, and reliability. These innovations are tailored to meet the evolving needs of modern manufacturing environments. Innovative designs enable manufacturers to optimize workflow efficiency and adapt quickly to changing production requirements, ultimately driving profitability and competitiveness in the market.

English

Français

Deutsch

Italiano

Select your language.

×

We use cookies to ensure that we give you the best experience on our website. If you continue to use this site we will assume that you are happy with it. Accept No Privacy policy