A precision chuck, in the context of manufacturing, is a specialized tool or device used to hold and secure a workpiece during machining or manufacturing processes. Chucks are commonly found in various machining operations, such as milling, turning, drilling, and grinding, where they play a crucial role in ensuring that the workpiece is held firmly and accurately in place.

Precision chucks are designed to provide a high degree of accuracy and repeatability in workpiece positioning and clamping. They are typically used when tight tolerances and precise machining are required. Some key characteristics of precision chucks include:

High Accuracy: Precision chucks are manufactured to tight tolerances themselves, ensuring that they can securely hold the workpiece with minimal runout or positional errors.

Repeatability: They allow for consistent and repeatable positioning of the workpiece, reducing the need for manual adjustments between machining operations.

Versatility: Precision chucks come in various types and configurations to accommodate different types of workpieces, including cylindrical, irregular, and non-standard shapes.

Quick Changeover: Some precision chucks are designed for rapid workpiece changeovers, which can help improve efficiency in manufacturing processes.

Common types of precision chucks include collet chucks, jaw chucks, magnetic chucks, and vacuum chucks, each tailored to specific machining applications. The choice of chuck depends on factors such as the workpiece geometry, material, and machining process requirements.

A precision chuck is a critical tool in manufacturing that ensures the accurate and secure holding of workpieces during machining, contributing to the overall quality and precision of the finished products.

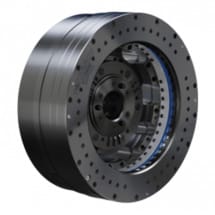

Diaphragm Chucks A diaphragm chuck works similar to the action of an oil can bottom. No sliding parts; no friction, no wear! It operates by a simple flexing action, assuring consistently controlled and accurate gripping.

Soft Touch Chuck Distortion-free workholding is now possible with the introduction of the Soft Touch chucking system. The unique design of this chuck allows clamp fingers to actually conform to a part’s natural, as processed contour.

3P110 Manual Chuck Experience the assurance of sealed design, preserving lubricant precisely where it’s needed. Achieve unparalleled <0.005mm accuracy with universal KDIN jaw mounting, ensuring low maintenance, cost-efficiency, and seamless compatibility with existing tooling.

BUCK TK Air-Operated 3-Jaw Buck pneumatic chucks offer precision and universal application use for turning machines at an affordable price. When looking for the perfect combination of light gripping and affordability, our TK product line is right for you.

English

Français

Deutsch

Italiano

Select your language.

×

We use cookies to ensure that we give you the best experience on our website. If you continue to use this site we will assume that you are happy with it. Accept No Privacy policy